Fencing mask facemask clip

Hold a disposable face mask inside your fencing mask with some simple clips that I’ve made. These are available in return for a donation via Paypal. Click the button below to order yourself some.

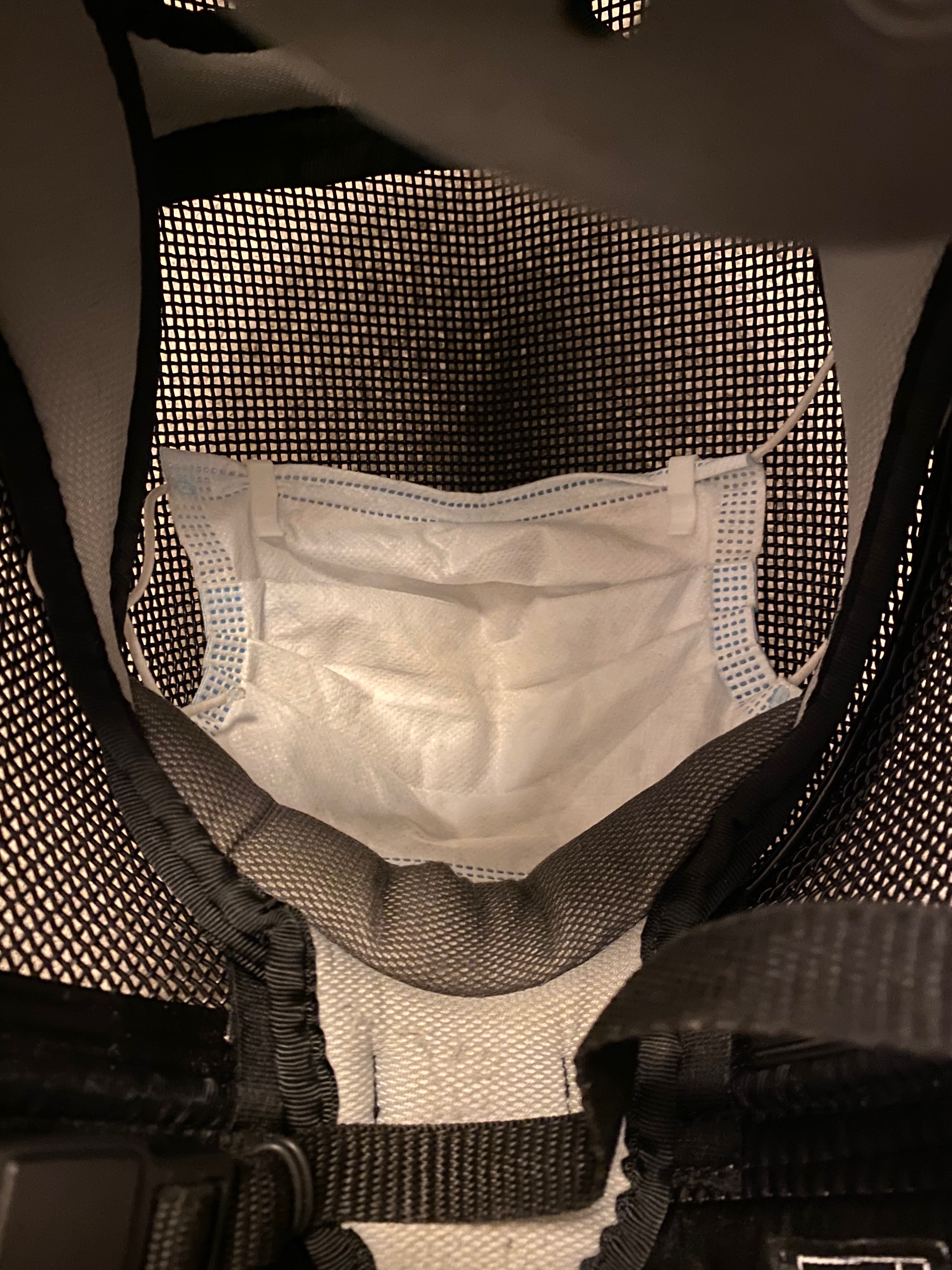

The COVID rules for Fencing in the UK (as of August 2020) suggest that fencers should wear a face mask or mask liner inside their mask. Face masks are hard to keep on your face if your mask is a close fit (it should be), and restrict your breathing. Wouldn’t it be better to hold a regular mask inside your mask without it falling off your face? This is the solution for that.

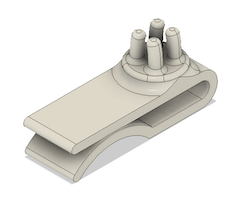

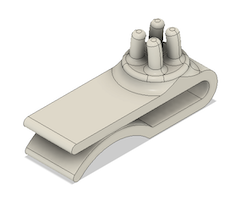

I’ve designed and produced some small clips that fit into the mesh of a fencing mask (confirmed to work with Leon Paul X-Change FIE, PBT FIE and Uhlmann (non FIE) masks). The clips allow you to place a disposable mask, or a washable cloth mask inside your fencing mask so that you can fence more easily. Because the face mask is held slightly away from your face, breathing is easier so you don’t get so hot and can carry on for a little bit longer.

Here’s how they fit into your mask:

# Design Work

The design uses a simple 4-pin clip system that I used to grip onto the wire mesh in the mask. This works better than a two-pronged affair because it helps to resist twisting which would cause the pins to shear. The pins curve together in pairs to grip around a stand of the mesh in the fencing mask. The main clip for the face mask is a simple curved clip that provides a grip on the face mask whilst also being gentle enough to be allow you to remove it.

The part itself is 3D-printed in PLA.

Finite Element Analysis (Now for the Engineering bit)

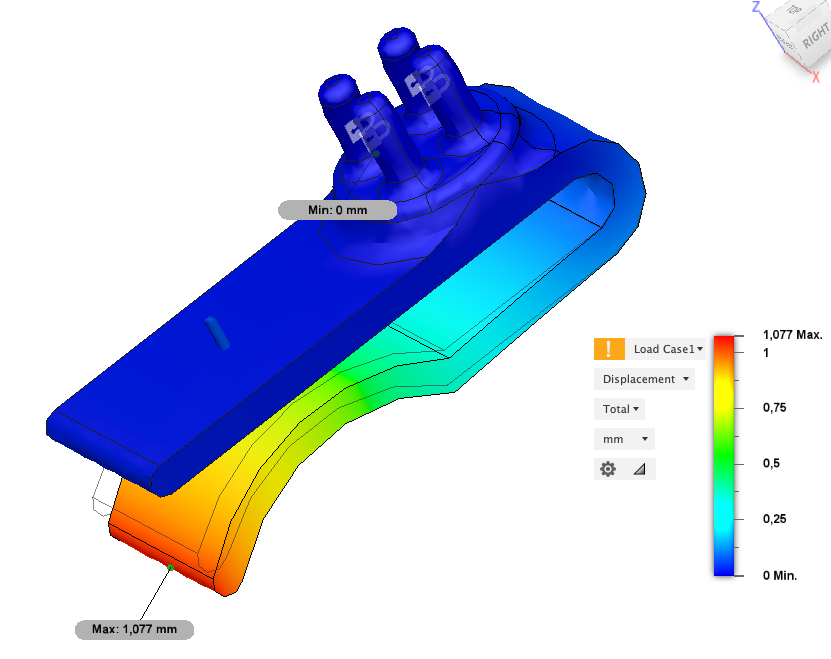

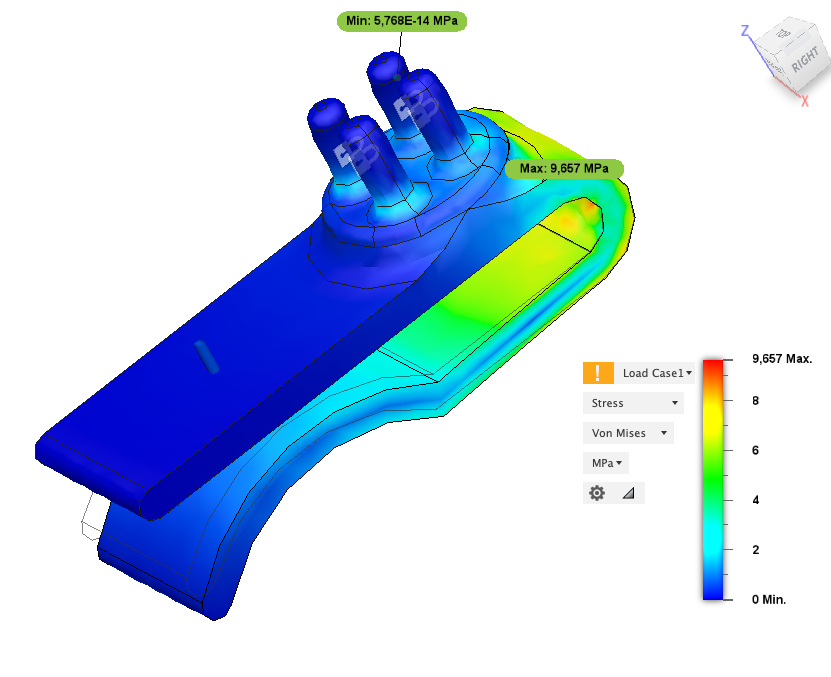

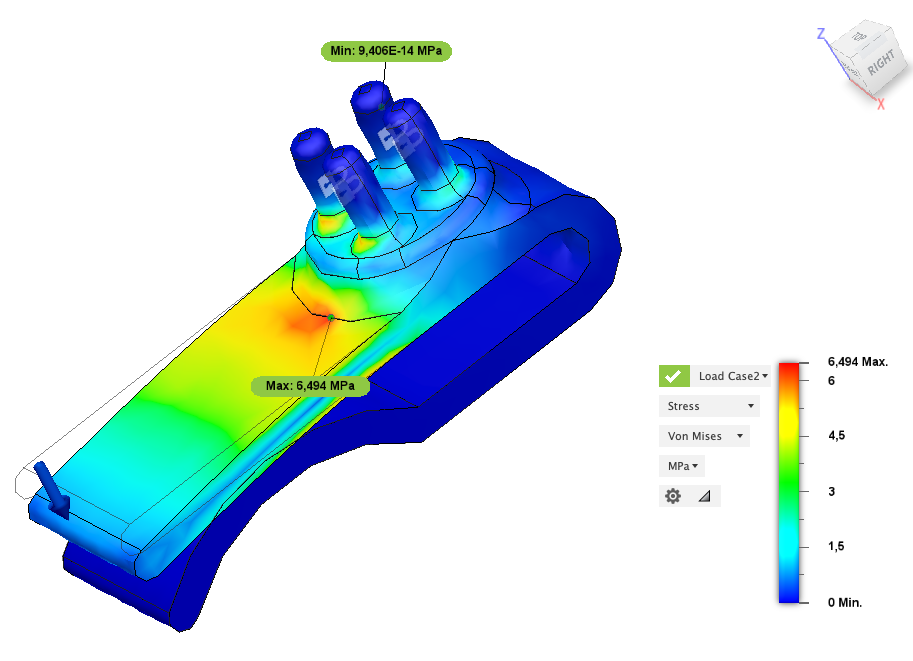

To complete the design work, I’ve done a quick spot of FEA to show whether the part is sufficiently strong for the job. I’ve only done a static stress model since I think it’s reasonable that the dynamic and thermally induced loads on this part are not important for its function. The model is set up with the faces of the clip pins as fixed constraints since they’ll be closely engaged with the mesh of the mask. I applied a load to the front face of the clip to simulate it being prized out of the fencing mask, and independently a load to the inside face of the clip to simulate fitting and removing the facemask.

The parts are printed in PLA, but I’ve simulated them in ABS since I don’t have the various parameters for PLA to hand. It’s also worth noting that the material is not isotropic (i.e. it has different strength values in different directions on account of being built up in layers). The absolute numbers are probably not valid, but the spirit is accurate enough to give a feeling for the strengths/weaknesses of this design.

# Load to clip detail

With 1N of force on the clip, we see that there is approximately 1mm displacement of the clip. This shows that the clip opens without completely falling apart.

There is quite a lot of stress in the curved section of the clip, so this is likely where it will fail if it’s bent too far out of shape (assuming that a weapon doesn’t break the tips of the clips off)

The Von Mises stress (which is a measure of the total load in the system, and can be used to work out whether a ductile material like 3D printed plastic will fail) shows a peak around the rear of the clip, and the safety factor here is only about 2. This suggests that the clip is weak at this point, but I would contend that strengthening in this area will cause the failure to more elsewhere (since we need the flex to grip the facemask) and thinning to allow more flexibility will reduce the grip strength of the clip.

# Load onto the rear of the clip

To simulate how the clip might be removed from a fencing mask, I applied a load to the rear of the clip which is similar to where it may be pried off a mask (you should really pull it out rather than peeling).

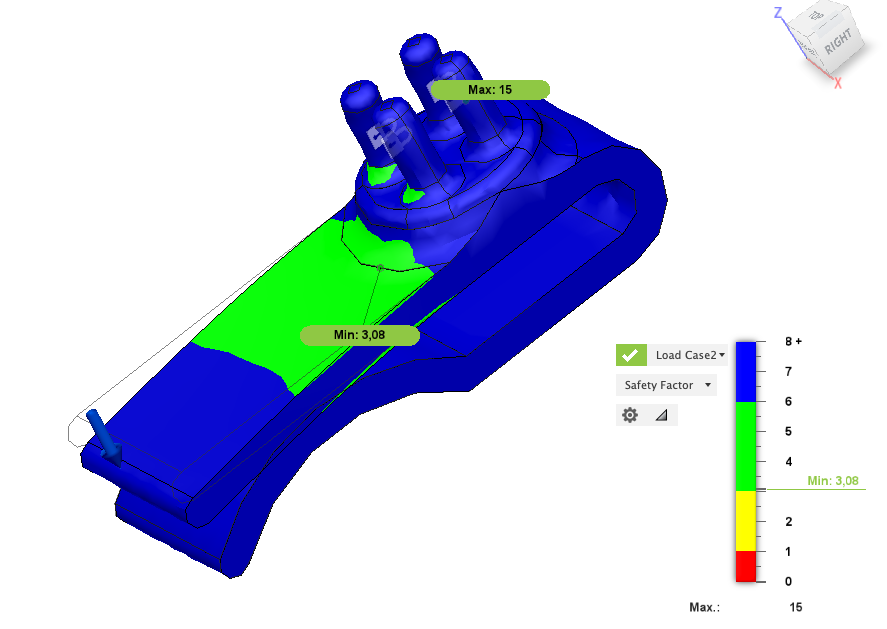

Here, there is some stress on the pins (as would be expected), but the peak is on the rear face. This is to be expected since the pins have been constrained to not move, which is a little unrealistic. The safety factor in this case is 3, which suggests that the design is up to this type of abuse, providing that a single pin doesn’t become the fulcrum of a lever (in which case, it’ll almost certainly break off).

Hope that you find this useful. Please consider purchasing some if you think that you’d like to give them a try.